Shunyata Research

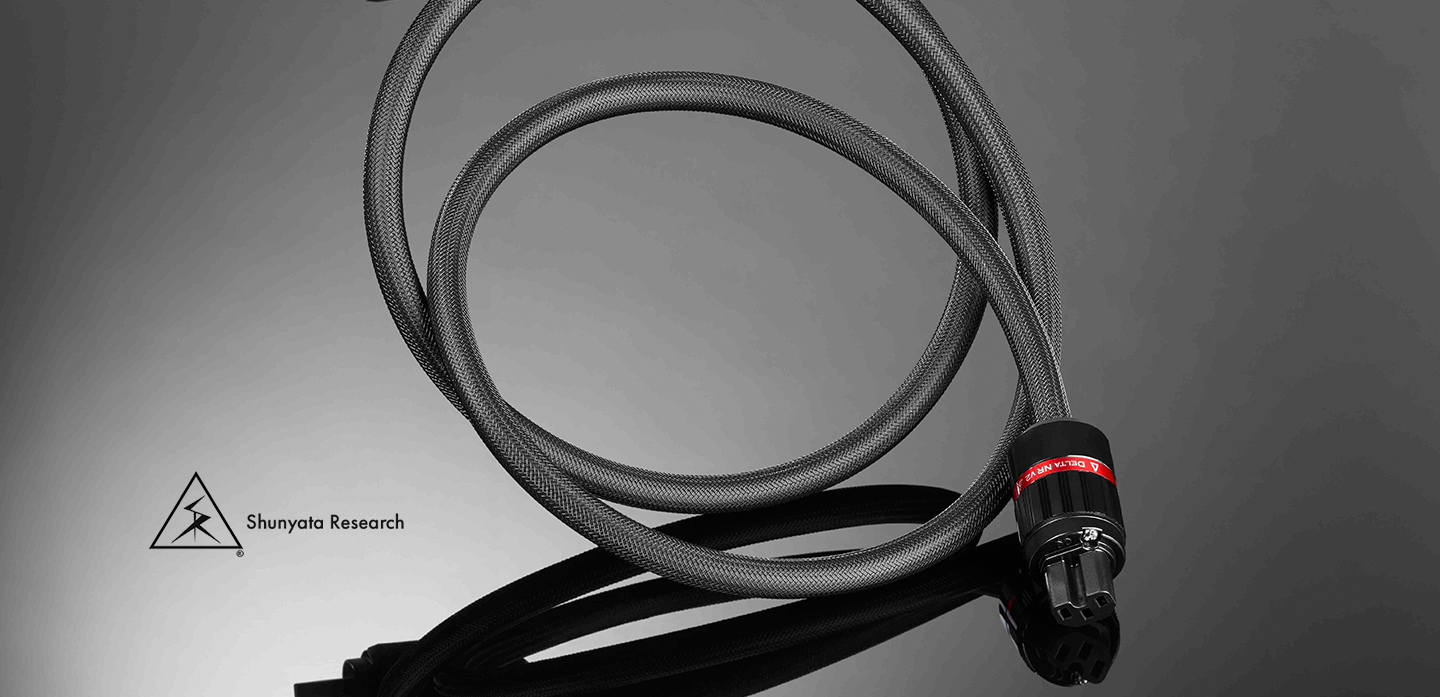

Shunyata Research are an American manufacturer whose cables are incredibly well respected the world over, in particular their power cables and conditioners are often described by many as the best in the industry. Having tested the Shunyata power cables extensively, we are very much of the opinion that they are a perfect addition to our unique range of world-class products. Shunyata design and produce all their cables themselves to extremely high standards in Seattle USA.

-

Latest

Shunyata Research£10,750Everest 8000 Mains Conditioner

Shunyata Research£10,750Everest 8000 Mains Conditioner -

Latest

Shunyata Research£5,500Typhon T2 Mains Conditioner

Shunyata Research£5,500Typhon T2 Mains Conditioner -

Shunyata Research£7,595Denali 6000/T UK Mains Conditioner

Shunyata Research£7,595Denali 6000/T UK Mains Conditioner -

Shunyata Research£5,900Hydra Alpha A10 UK Mains Conditioner

Shunyata Research£5,900Hydra Alpha A10 UK Mains Conditioner -

Shunyata Research£3,500Hydra Delta D6 UK Mains Conditioner

Shunyata Research£3,500Hydra Delta D6 UK Mains Conditioner -

Shunyata Research£2,500Venom V6 Mains Conditioner

Shunyata Research£2,500Venom V6 Mains Conditioner -

Latest

Shunyata Research£3,000Altaira Grounding Hub

Shunyata Research£3,000Altaira Grounding Hub -

Shunyata Research£9,000 – £14,160Omega QR UK Mains Cable

Shunyata Research£9,000 – £14,160Omega QR UK Mains Cable -

Shunyata Research£7,500 – £11,700Omega QR-S UK Mains Cable

Shunyata Research£7,500 – £11,700Omega QR-S UK Mains Cable -

Shunyata Research£7,000 – £11,550Omega XC UK Mains Cable

Shunyata Research£7,000 – £11,550Omega XC UK Mains Cable -

Shunyata Research£3,000 – £3,392Omega Ethernet Cable

Shunyata Research£3,000 – £3,392Omega Ethernet Cable -

Shunyata Research£4,500 – £5,890Omega Clock Cable

Shunyata Research£4,500 – £5,890Omega Clock Cable -

Shunyata Research£800 – £1,290Omega CGC/SGC Ground Cable

Shunyata Research£800 – £1,290Omega CGC/SGC Ground Cable -

Shunyata Research£3,500 – £4,940Sigma V2 NR UK Mains Cable

Shunyata Research£3,500 – £4,940Sigma V2 NR UK Mains Cable -

Shunyata Research£3,250 – £5,330Sigma V2 XC UK Mains Cable

Shunyata Research£3,250 – £5,330Sigma V2 XC UK Mains Cable -

Shunyata Research£2,000 – £2,392Sigma Ethernet Cable

Shunyata Research£2,000 – £2,392Sigma Ethernet Cable -

Shunyata Research£2,250 – £2,930Sigma Clock Cable

Shunyata Research£2,250 – £2,930Sigma Clock Cable -

Shunyata Research£500 – £860Sigma v3 CGC/SGC Ground Cable

Shunyata Research£500 – £860Sigma v3 CGC/SGC Ground Cable -

Shunyata Research£2,500 – £4,330Alpha V2 NR UK Mains Cable

Shunyata Research£2,500 – £4,330Alpha V2 NR UK Mains Cable -

Shunyata Research£2,300 – £3,730Alpha V2 XC UK Mains Cable

Shunyata Research£2,300 – £3,730Alpha V2 XC UK Mains Cable -

Shunyata Research£1,250 – £1,642Alpha Ethernet Cable

Shunyata Research£1,250 – £1,642Alpha Ethernet Cable -

Shunyata Research£1,500 – £2,040Alpha Clock Cable

Shunyata Research£1,500 – £2,040Alpha Clock Cable -

Shunyata Research£400 – £720Alpha v3 CGC/SGC Ground Cable

Shunyata Research£400 – £720Alpha v3 CGC/SGC Ground Cable -

Latest

Shunyata Research£1,100 – £1,685Theta NR UK Mains Cable

Shunyata Research£1,100 – £1,685Theta NR UK Mains Cable -

Shunyata Research£1,100 – £1,685Theta XC UK Mains Cable

Shunyata Research£1,100 – £1,685Theta XC UK Mains Cable -

Shunyata Research£2,000 – £2,750Theta Speaker Cable

Shunyata Research£2,000 – £2,750Theta Speaker Cable -

Shunyata Research£1,200 – £2,560Theta XLR Balanced Interconnect

Shunyata Research£1,200 – £2,560Theta XLR Balanced Interconnect -

Shunyata Research£1,000 – £2,360Theta RCA Interconnect

Shunyata Research£1,000 – £2,360Theta RCA Interconnect -

Shunyata Research£1,100 – £2,460Theta Phono Cable

Shunyata Research£1,100 – £2,460Theta Phono Cable -

Shunyata Research£650 – £1,040Gamma NR UK Mains Cable

Shunyata Research£650 – £1,040Gamma NR UK Mains Cable -

Latest

Shunyata Research£650 – £1,040Gamma XC UK Mains Cable

Shunyata Research£650 – £1,040Gamma XC UK Mains Cable -

Shunyata Research£1,000 – £1,480Gamma Speaker Cable

Shunyata Research£1,000 – £1,480Gamma Speaker Cable